It is an ideal choice for removal of condensate from process heating equipments such as heat exchangers, storage tank coils, drying cyclinders, jackets, reactors, jacketed vessels, ovens etc.

Features

- Rotary slide mechanism modulates condensate flow at all load levels

- Alteration of flow direction at site possible

- Continuous discharge of condensate

- Wider condensate drain area ensures no choking orifice unlike other traps

- Fusion welded ball floats ensure longer working life.

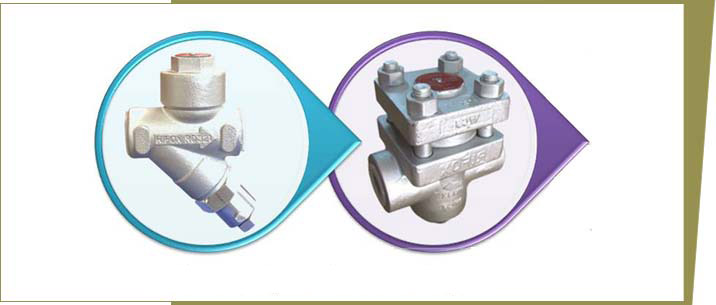

It is a stainless steel body balanced pressure thermostatic steam trap with a built in strainer, ideal for removal of condensate from instrumentation tracing lines.

Product Features

- Provided with built in strainer

- Membrane capsule regulator resists corrosion and is unaffected by water hammer

- Discharge condensate below saturation temp leading to increased heat recovery from condensate

- Available in forged carbon steel & SS body.

It is a stainless steel body balanced pressure thermostatic steam trap with a built in strainer, ideal for removal of condensate from instrumentation tracing lines.

Products Features

- Stainless steel body

- Built in strainer

- Automatic air venting at startup and during operations.