The hot water is generated by indirect heating of water in a heat exchanger with steam as the heating medium. It is ideally suited for pharmaceuticals, breweries, textiles, hospitals & hotel industry.

Product Features

- Instantaneous generation of hot water – Less warm up time

- Skid mounted assembly – Compact, minimum floor space required, simpler plant structure, easy installation at sight

- Pump and trap combination – No stall conditions

- Accurate temperature control – Desired temperature output

- Easy installation and commissioning

- Heat treated and nitrided internals of valve – Prevents erosion, wire drawing effect

Pressurised Deaerator - is a system designed to heat boiler feed water in order to reduce oxygen and carbon dioxide level to reduce corrosion of boiler internals, tubes, etc. Thermax pressurised deaerator economically handles wide range of flow rates & temperature for both boiler feed water & process applications.

- This is very powerful steam and condensate system for paper machine

- This system is usually suitable for high speed high capacity machine.

- In this system there is no need for steam traps

Thermo-compressor

Mixture of motive steam and entrained fluid (e.g., low pressure steam) is re-compressed through the diffuser, which converts velocity to pressure energy. The re-compressed vapor can be reclaimed back to the process

Qcal (Heat Meter)

Qcal (Heat meter) is an online metering system installed at the outlet of Thermic Fluid Heater/ Hot Water Generators/process equipments to measure heat input to process equipment / heat generation by heater.

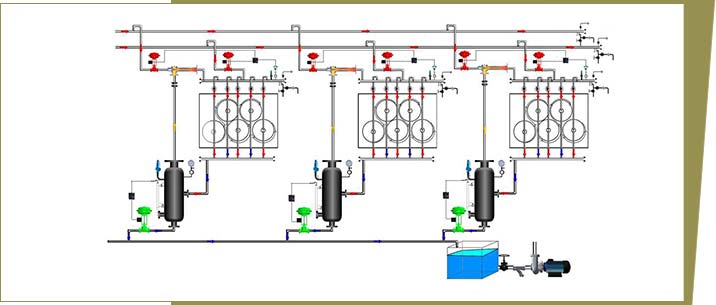

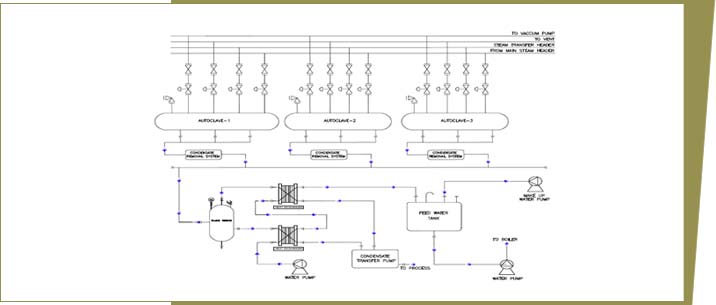

Thermax offers Process Automation for Aerated Autoclaved Concrete (AAC) Industry. These industries require large amount of steam at comparatively high pressure. Major steam usage is for heating and curing of green cake of concrete block inside the Autoclave.

Complete process involves Vacuuming, Heating, Curing (Holding), Transfer and venting cycles. It requires precise control on Vacuum time, Heating Temperature gradient, Curing cycle timing, Steam transfer and Venting process. Condensate removal from Autoclave is very important as it is contaminated with cement particles and may leads to chocking of condensate removal system.

Thermax Offers system consisting of Control Valves, Bellow Seal isolation valves, Pressure transmitters, Temperature transmitters & Condensate removal system which operates based on PLC control. With PLC System customer can monitor and maintain the required process parameters. The system also provides output in the form of graphs and charts for various critical parameters to control the system effectively.

Since condensate is contaminated with cement particles, condensate recovery back to boiler feed water tank is not recommended. It is recommend recovering condensate heat for heating fresh makeup water in a proposed heat exchanger.

System Benefits

- User friendly System and ease of operation

- Precise control on critical pressure and temperature parameters

- Proper utilization of vent steam in another Autoclave during the transfer cycle

- Level based condensate removal system to avoid chocking of condensate lines

- Condensate and flash steam heat recovery for fresh makeup water heating

- Contaminated condensate and flash steam both water recovery for slurry preparation.

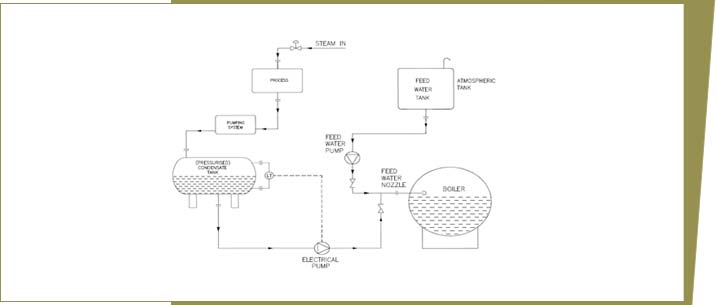

Thermax offers High Pressure Condensate Recovery System (HPCRS) where recoverable condensate is more than 80% of the total steam consumption. The term HPCRS refers to recovering the condensate directly to the boiler shell and injecting it into water space without entering it into feed water tank.

With this system we eliminate condensate flashing as flashing reduces the pressure and temperature of condensate. The heat of both flash steam & condensate cannot be held by BFW in a FW tank as, feed water temperature is likely to go above 100 deg C if condensate & flash are recovered in FW tank.

Also since condensate temperature is close to saturation, significantly less fuel is required to generate the same amount of steam. The system is estimated to give fuel saving between 10 to 20 %, when compared with conventional atmospheric condensate recovery system.

HPCRS is operated by PLC based controlled system with key specialized products like high temperature Centrifugal Pump, Control valve, Pressurized tank, Condensate pumping system to handle very high condensate temperature and as well as pressure.

Benefits of HPCRS

- 100% condensate heat and water Recovery is achievede

- No flashing of condensate either at process house or at feed water tank within the Boiler House

- Boiler Operating Capacity is enhanced

- Due to high temperature condensate entering water space, steam pressure fluctuation eliminated

- Saving in water treatment cost

- Saving in water due to flash recovery as against conventional condensate recovery system

Potential Industry for HPCRS

- Corrugated Box Manufacturing

- Plywood Industry

- Tyre Manufacturing / Rubber Vulcanizing / Tyre Retreading / Rubber belt Manufacturing

- Rice Mills

- Tea Industry

- Paper Industry