AquaeroTherm- A Revolutionary Heating Solution for Tea Drying

Thermax changed the way tea has been dried traditionally, by introducing high efficiency, indirect heating systems in place of conventional, low efficiency, air-to-air hot air generators.

The use of different heating media such as steam, thermic fluid and hot water has led to significant gains in thermal efficiency.

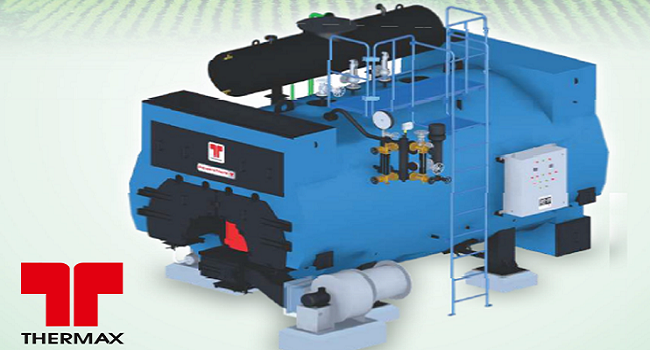

Aquaerotherm from Thermax

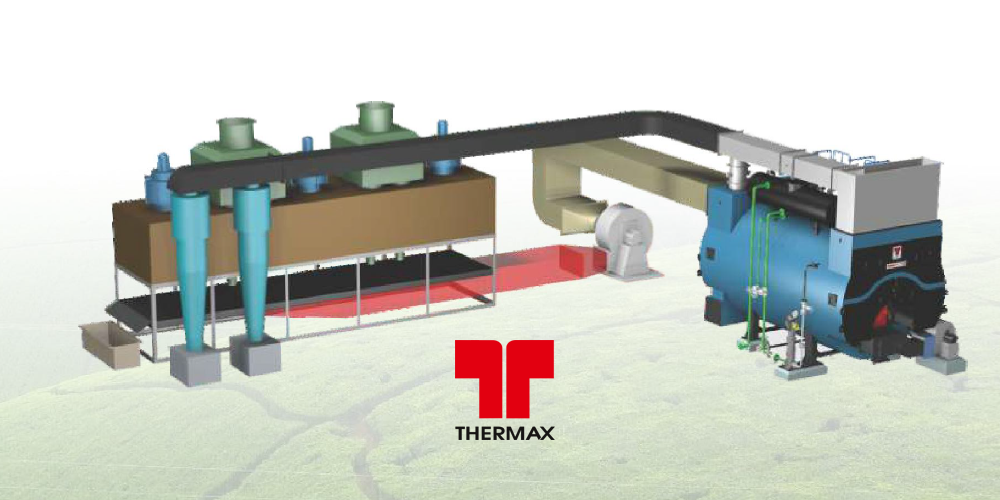

Indirect heating systems are more complex, since they need additional equipment such as external radiators and pressurized pumping systems using heating media such as water/ thermic fluid.

Thermax presents Aquaerotherm (ATM), the next generation indirect heating system, which provides highest thermal efficiency up to 82%. Further, it eliminates the complexity of using an external radiator, pressurized pumping system and replacement of heating media like water/thermic fluid. The ATM also comes with an in-built radiator, thus eliminating the need for an external radiator and pumping system, and the system is pressurized using heating media via steam.

High performance features

- High system efficiency

- High quality drying

- Power savings

- Steady hot air temperature to process

- Options for energy Savings

- Controls and safeties

ATM offers higher thermal efficiency, when compared to direct air heaters. Also, it has the capability to enhance efficiency further with the addition of a heat recovery unit.

ATM provides clean hot air to the process, thus eliminating the possibility of smoke taints in tea, and preventing over and under firing during tea drying.

Lower excess air results in lower power consumption by the forced Draft and Induced Draft fans.

There outlet air temperature is ensured by steady steam pressure and large water hold up in ATM, thus ensuring consistent quality of tea.

ATM offers additional heat recovery in the form of air preheater, for increasing thermal and system efficiency.

ATM comes equipped with the following control and safety interlocks, to handle abnormal working conditions.likewise -Water level Controller, High steam pressure, High outlet process air temperature, High flue gas temperature.

Call Us Now

Call Us Now